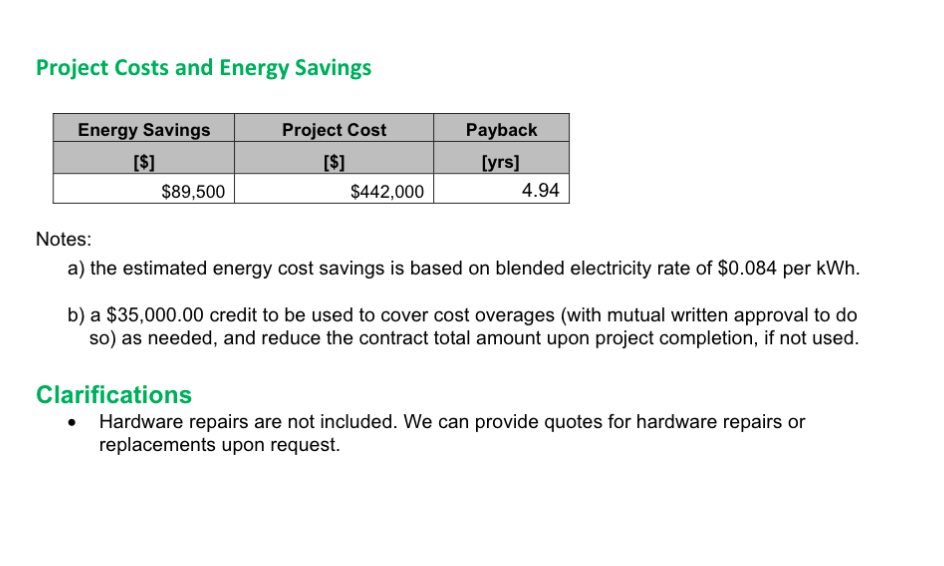

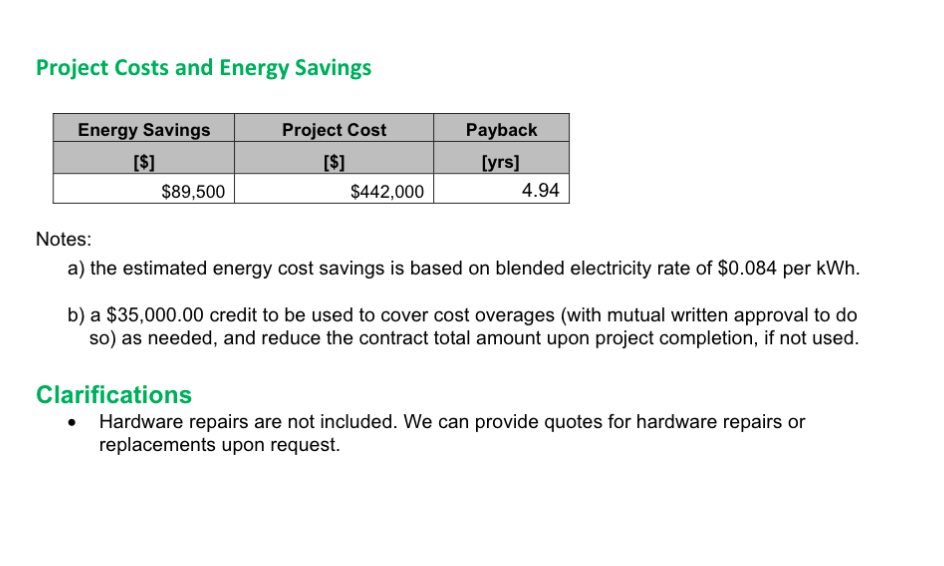

This client had $310,00.00 in expenses for a building management system with no energy reduction. We rewrote the AHU sequences in the client energy model and optimized their controls. This energy retrofit resulted in $89,000.00 in annual savings for the client with a 4.9ROI.

Scope of WorkECM-1. Install VFDs for AHU fans and pumps at chiller plant

- All AHUs (10 hp each, Qty 24)

- Chilled water pumps (25 hp each, Qty 2)

- Condenser water pumps (20 hp each, Qty 2)

- Hot water pumps (20 hp each, Qty 2)

ECM-2. Control Upgrade

AHUs serving the retail space (Qty 14)

- Remove existing pneumatic controls•Install and program new BACNET IP controllers

- Install new temperature sensors•Install new space temperature sensor / thermostats

- Install new EP transducers to control existing pneumatic valves

- Install new IP connections (network switches and cables)

AHUs serving the Tower (Qty 10)

- Remove existing Carrier controllers

- Install and program new BACNET IP controllers

- Reuse existing temperature sensors and pneumatic valves

- Install new IP connections (network switches and cables)

Chiller and boiler plant

- Install and program new BACNET IP controllers with adequate IO modules

- The new controllers will control all major equipment including chillers, boilers, pumps, cooling towers, valves, etc.

- Install new sensors where necessary and re-use existing sensors

- Install new IP connections (network switches and cables)

Miscellaneous

- Install new CO2 sensors in representative locations to monitor building ventilation

- Install a new building pressure sensor to monitor building pressurization

- Install an outside air temperature / humidity combo sensor

Building Automation System

- Install a new cloud-based BAS based on latest Niagara-platform

- Install supervisor license on a new server PC

- Integrate all IP devices into the supervisor

- Create graphics for all major HVAC systems and equipment

- Setup schedules, alarms and trends

- Alarm notifications can be sent through emails or text messages to designated personnel with manageable escalation schemes (internet required).

- Weather data (and forecast) can be made directly available to BAS through internet from selected weather station(s) to help BAS and building operators making operational decisions

ECM-3. HVAC optimization

Central Utility Plant

- Optimize and reset chilled/hot water loop differential pressure (DP) set points based on building demand and/or weather conditions

- Implement/optimize chilled/hot water temperature set point reset based on weather and load conditions

- Optimize and reset condenser water temperature set points based on outside air wet bulb temperature

- Control and optimize condenser water pump speeds based on chiller load and condenser water differential temperature

- Optimize cooling tower fan staging and fan speed control

- Optimize chiller staging control for overall maximum plant efficiency

- Automate and optimize switching between heating and cooling based on weather and/or room conditions(1)

AHUs

- Implement on/off scheduling and optimal start/stop for applicable units

- Implement night setback for applicable units•Implement demand-based ventilation for tower units

- Implement single zone VAV strategy for retail space to improve comfort control and save energy

- Optimize discharge temperature set points for tower AHUs based on weather and/or room conditions(1).

Notes 1. Room controls need to be upgraded for BAS to gather room conditions data.